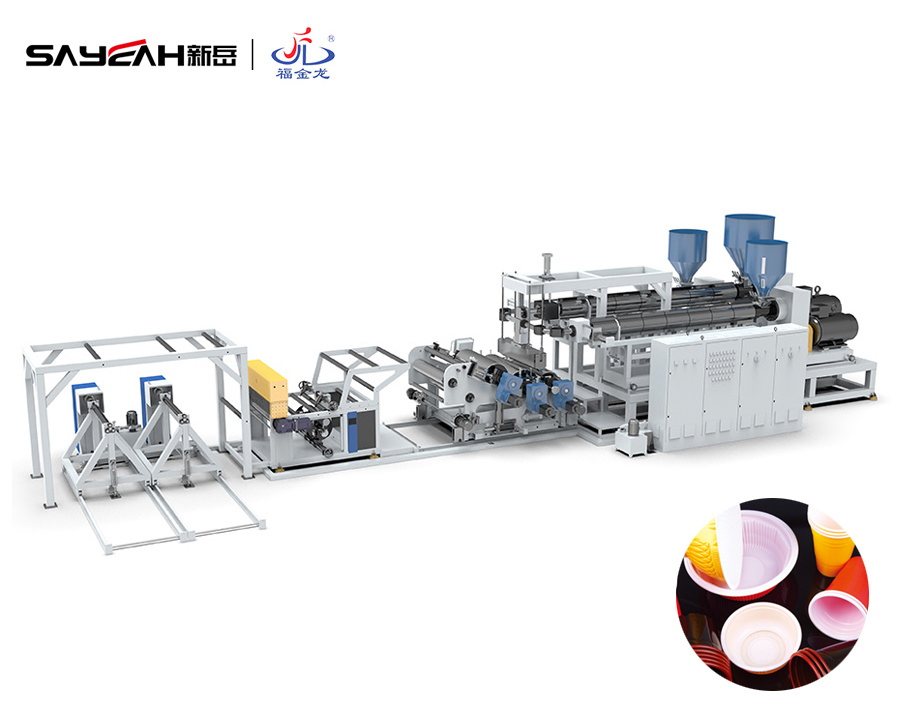

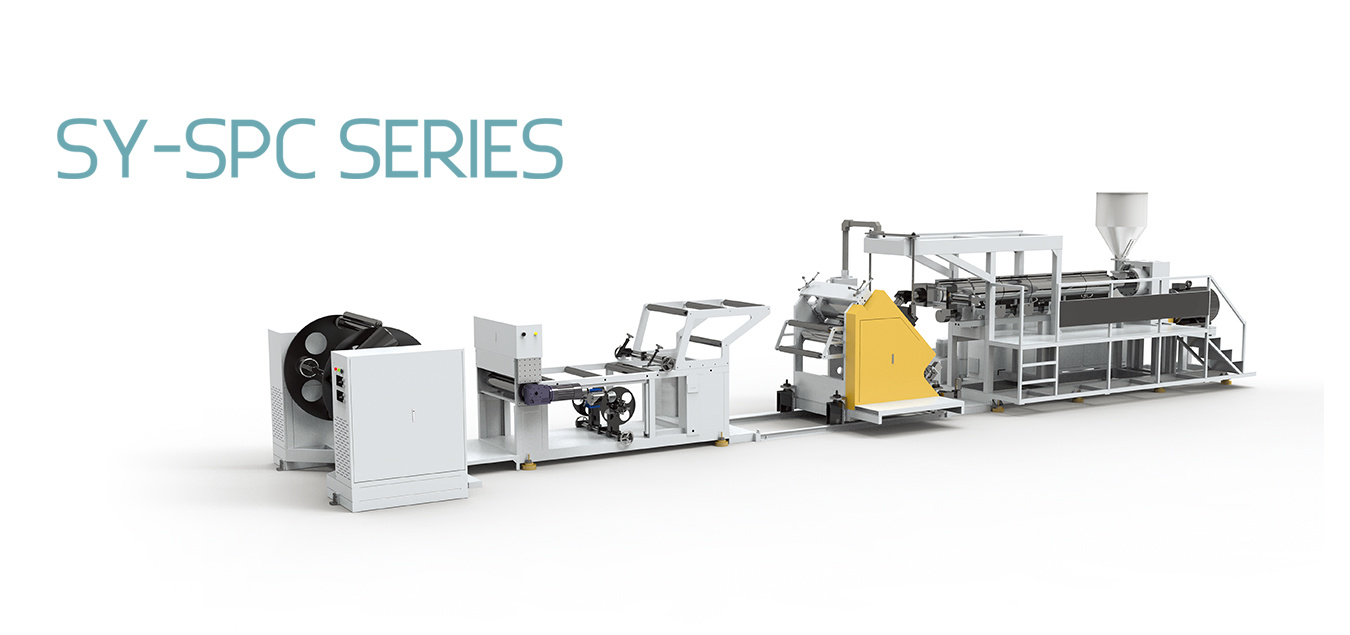

SY-PC-A SERIES Diagonal Mono-Layer Plastic Sheet Extruder

Category:

Sheet Extrusion Line

Product description

Major Construction Features

1. The sheet extrusion unit is a combination of extruder,three roll calenders,haul-off unit,winder(including waste sheet winder) and electric control cabinet.

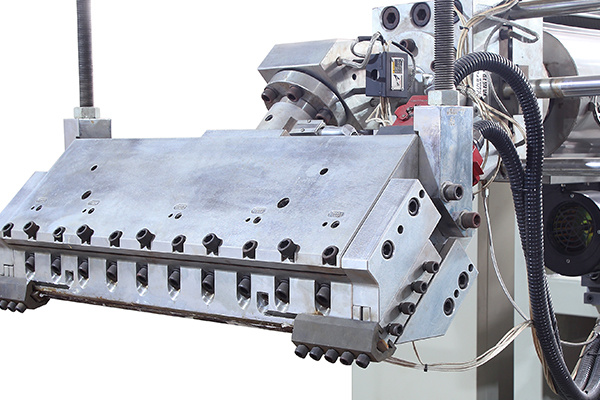

2. The main parts, such as screw, barrel, screen exchanger, T-die adopt superior alloy steel(38 CrMoAIA) with high hardness, strong corrosions resistance and long operating life after nitrogen treatment.

3. The screw adopts big L/D ratio,equal plasticization and high plasticizing capability.

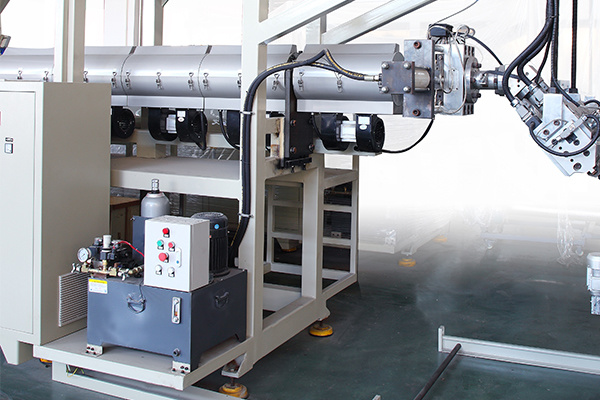

4. Non-stop fast screen changer with double-sieve, controlled by hydraulic device, the operation is convenient and improve the production efficiency.

5. The calendar,haul off unit and winder adopt integration design,fine appearance,convenient and improve the production efficiency.

6. The machine frame adopt square steel, to make sure the machine works stably in high speed. The motor is connected with gear box directly, improve production efficiency and lower energy consumption.

Note: Special specification and configuration of products can be designed according to customer’s demand.

Main Technical Parameters:

| Model | SY-PC-90-A | SY-PC-110-A | SY-PC-120-A |

| Raw Material | PP,PS,HIPS,PE | PP,PS,HIPS,PE | PP,PS,HIPS,PE |

| Sheet Thickness | 0.3-2mm | 0.3-2mm | 0.3-2mm |

| Layer | 1 | 1 | 1 |

| Extrusion Capacity | 100kg/h | 200kg/h | 250kg/h |

| Screw Dia. | 90mm | 110mm | 120mm |

| L/D Ratio | 33:1 | 33:1 | 33:1 |

| Roller Dia. | Φ350mm x 3 | Φ350mm x 3 | Φ400mm x 3 |

| Main Motor Power | 37kw | 55kw | 110kw |

| Overall Power | 90kw | 120kw | 160kw |

| Weight | 5.5T | 7T | 8T |

Notes: If any change of data, we will not notify further

|

|

|

|

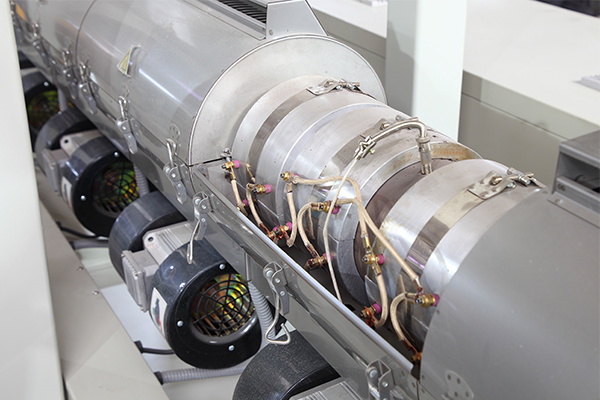

The feeding barrel adopts a transparent slotted design so that you can see the remaining material in the barrel and feed the material in time. The screw feed trough adopts a water-cooled design to prevent the blockage of the feed trough caused by melt backflow. |

The screw is heated by 6-stage cast aluminum heating tile, using wear-resistant material 58Cr13, and the hardness reaches HV950. |

|

|

| The feeding barrel adopts a transparent slotted design so that you can see the remaining material in the barrel and feed the material in time. The screw feed trough adopts a water-cooled design to prevent the blockage of the feed trough caused by melt backflow. | The screw is heated by 6-stage cast aluminum heating tile, using wear-resistant material 58Cr13, and the hardness reaches HV950. |

|

|

| The screen changer adopts double stations hydraulic pressure to ensure the screen changes without stopping and uses 38CrMoAIA high-quality material to prolong the service life. | Using high-precision T-die, which is made of high-quality alloy steel, the inner flow channel is chrome-plated. It has high hardness and strong corrosion resistance capacity. |

|

|

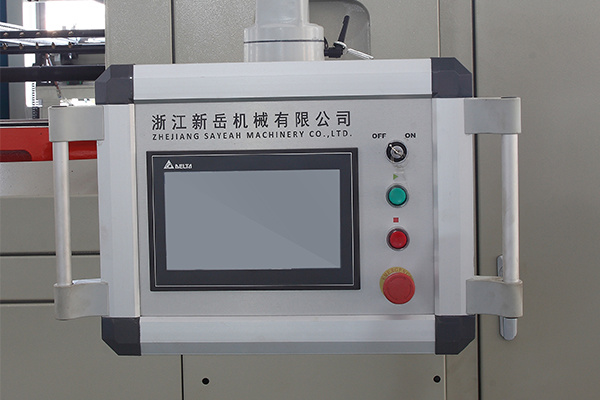

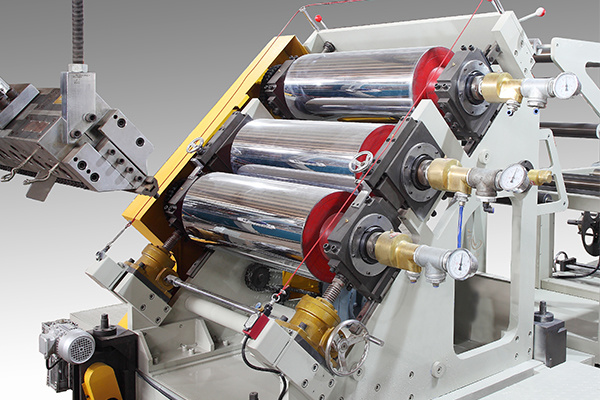

| The response is fast and no delay by using Delta's industrial control touch screen. The operation interface is simple and easy. | The calendering three-roller adopts 0.08mm chrome-plated layer, and the hardness can reach HRC58-62. The design of the safety rope can stop the machine immediately in case of an accident, improving safety effectively. |

|

|

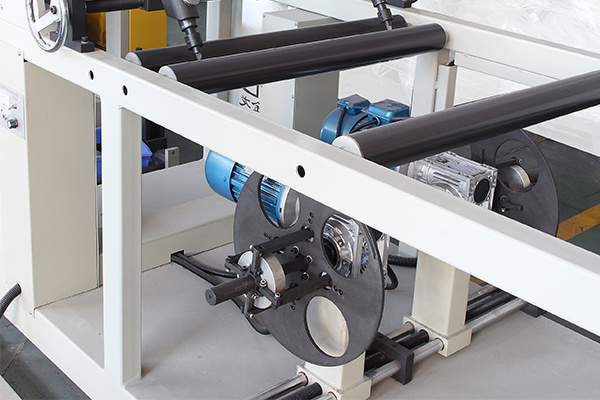

| Two pair knives can adjust the trimming width and depth。The trimming and winding device is driven by an independent motor, it can be used with online-crusher | Double-station non-stop rewinding device is driven by the torque motor. It has 6-speed adjustable torque, equipping a quick-release rewinding device, which can save your time and effort. |

RELATED PROUCTS